System partner for customized valve solutions

Since November 2020, we, VOSS Automotive Valves and Actuators GmbH, formerly HENZEL Automotive GmbH (HFG), are another important part of the globally operating VOSS Group, a market leader for line and connection systems for the automotive industry and mechanical engineering.

We develop and manufacture future-oriented, fluid-carrying components made of plastics and thus excellently complement the existing VOSS product portfolio.

As a new organization in the VOSS Group, we will henceforth operate as a competence center for innovative valve technology in thermal management applications. We realize function-integrated systems for battery temperature control in electric and hybrid vehicles specifically according to customer requirements.

This includes the integration of valves, lines, manifolds and customized components into ready-to-install modules.

Competences

Development & Design

We find "the" innovative solution for your applications. We develop initial ideas and let them mature into a technologically high-quality product together with you. In doing so, we can rely on the extensive know-how of our motivated and specialized employees. Fluid-carrying plastic components and function-integrated system solutions are our specialty.

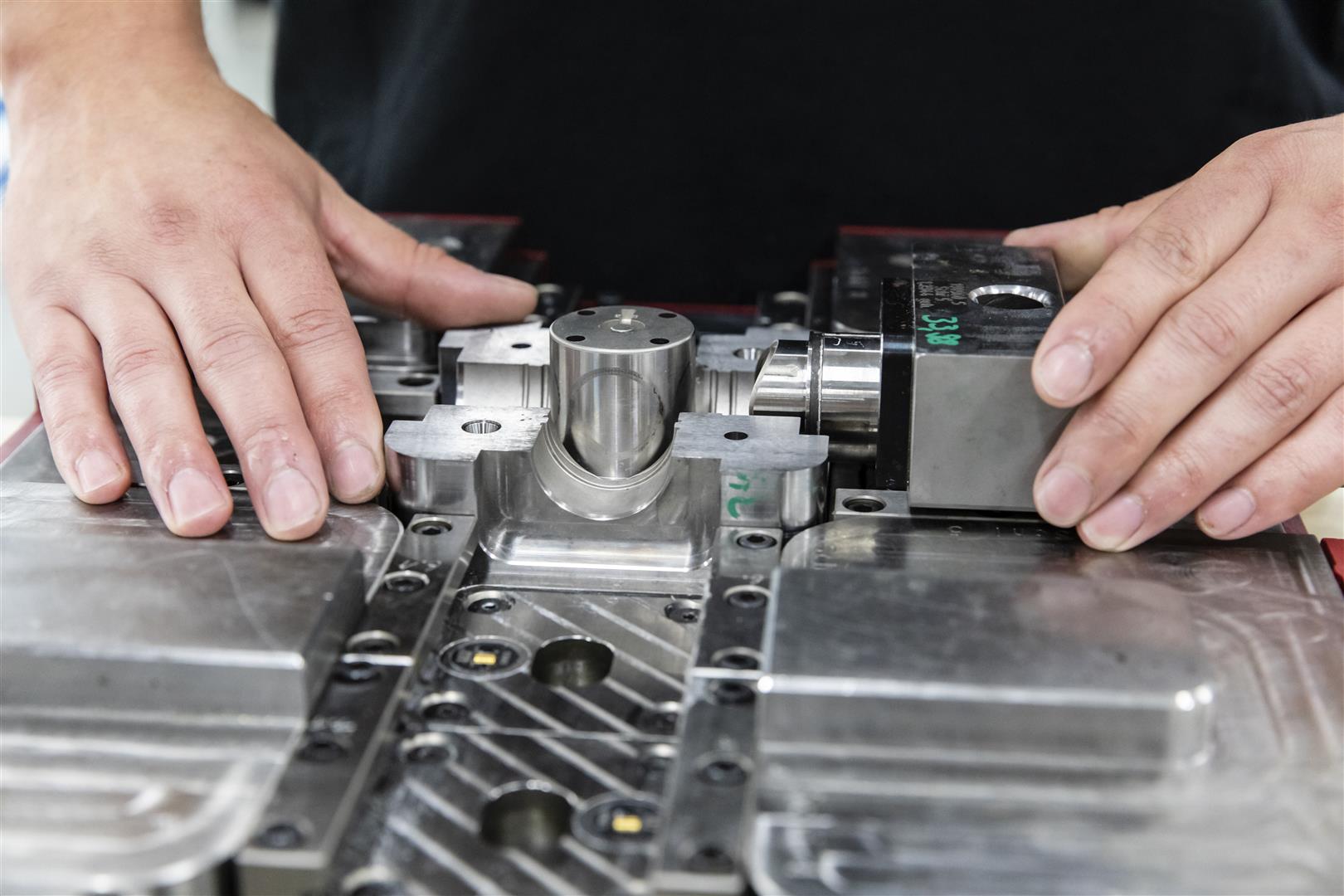

Tool construction

Due to our own tool construction, equipped with the latest processing machines, we are able to manufacture our prototype and series tools as well as automatization components very efficiently. Just as quickly as flexibly, we implement changes and maintenance in-house at short notice.

Production

Our constantly growing machine park consisting of a large number of injection molding machines in a wide variety of designs for processing various types of plastic guarantees the production of customer-specific components at the highest product quality.

Assembly

The final assembly of the individual components is accomplished by various manual assembly and fully automatic machines. Thereby, the highly specific machines not only fulfill various assembly and joining processes but also parallel quality checks, such as leak tests, camera inspections and laser marking.

Welding processes

For the assembly process of plastic components we use various mating techniques, such as friction welding, laser welding and ultrasonic welding. The machines used are produced in-house.

Industrialization & Automation

The planning and production of our assembly systems is handled in-house. This enables us to design and lay out our machinery according to quantities, assembly size and customer requirements.

Quality management

As a supplier to the automotive industry, we have the necessary certifications, IATF 16949:2016 as well as DIN EN ISO 9001:2015. To meet our own quality requirements, but also those of our customers, we use a wide range of transparent processes and production standards, such as store floor management. The latest testing and measuring equipments help us to avoid defects or to detect and eliminate them at an early stage.

In addition, we pursue a zero-defect strategy with the highest level of quality awareness in all areas of our company. Our motivated employees live this claim with infectious passion and contribute significantly to continuous improvement in their daily processes.

Responsibility

We stand for a sustainable and responsible management in dealing with energy and resources. This applies both to the development of our products for future-oriented, low-emission drive technologies and to our entire business activities, from procurement and processing to the disposal of materials and equipment.

The health and protection of our employees are also very high priorities for us. Health-promoting measures and regular training and instruction ensure that working at our site is virtually accident-free.